HOTMELT

2-layer

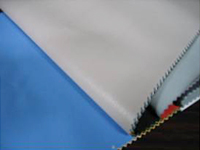

- The 2-layer HOTMELT process involves transferring an eco-friendly hot melt adhesive to TPU (Thermoplastic Polyurethane)

and R/P casting films, which are then bonded under controlled temperature and humidity conditions.

- DOT Lamination : Known for its high breathability and soft texture.

- Product Details : Membrane film and adhesive are applied on release paper and then laminated with the fabric, resulting in a high-performance product with excellent feel and stretchability.

- Customization : Patterns can be freely selected based on usage and coating weight, offering superior wash durability compared to solvent-based adhesives.

- Material Compatibility : Can be widely applied to materials sensitive to heat or tension.

- High-Performance Films : In addition to using films like DuPont and Sympatex, Deukgeum's proprietary high-performance casting films are also applicable.

3-layer

- The 3-layer HOTMELT process is suitable for fabrics sensitive to tension, such as spandex fabrics.

It involves laminating the outer fabric, membrane, and inner lining to create a 3-layer structure.

- Product Details : It can be applied to various linings to create a 3-layer fabric,

or simply bonded without additional layers.

- Customization : Allows for the creation of diverse 3-layer products to meet specific customer requirements.

- These HOTMELT processes offer advanced solutions for high-performance, durable, and versatile laminated fabrics suitable for various applications.