Product Description

R/P LAMINATION

In the R/P lamination process, a coating liquid is applied on release paper to form a desired film, which is then laminated with a fabric substrate having the required properties. This process produces coated fabrics with various functional properties.

Our main products using this method include breathable and waterproof fabrics for sportswear such as hiking, golf, and skiing, as well as special workwear for industrial environments and coated fabrics for automotive interiors.

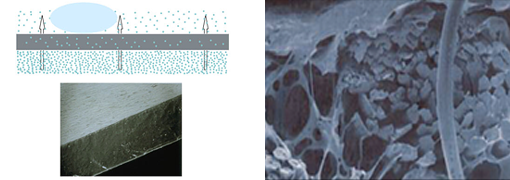

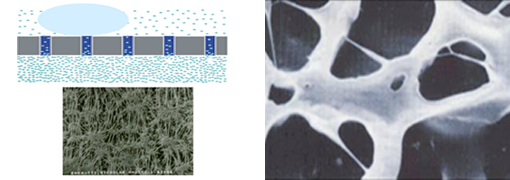

DKTNC use both Hydrophilic (non-porous) and Micro-Porous (microfine pore) type films.

Hydrophilic (Non-Porous) Type

Micro-Porous Type

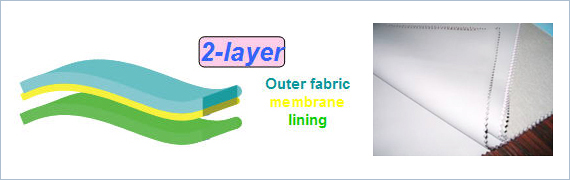

2-layer

Full or Dot Adhesive Lamination Products : Dot lamination boasts high breathability and a soft texture.

Product Details : Membrane film and adhesive are applied on release paper and then laminated with the fabric.

The result is a high-performance product with excellent feel and stretchability.

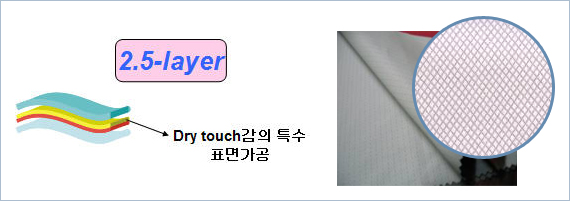

2.5-layer

Instead of lining, the backside of the membrane features numerous small dots that can withstand abrasion.

Advantages : These products are about 10-20% lighter than traditional 3-layer products, with negligible bulk relative to size and weight.

Development and Production : We are developing and producing various patterns and can customize products to meet customer requirements.

Additionally, we manufacture seam tapes in-house and can process various patterns through printing.

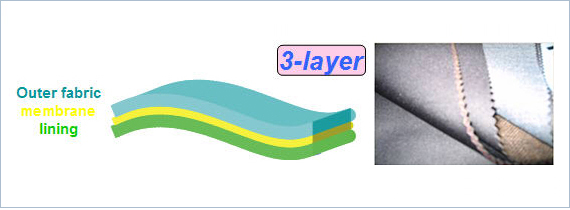

3-layer

Product Details : The breathable and waterproof functional PU fabric has a secondary fabric laminated to the backside of the membrane.

Customization : Bonding fabrics are laminated based on customer requests. We have a wide range of 3-layer product samples available.

Our advanced processes and versatile production capabilities allow us to meet diverse customer needs with high-quality, functional coated fabrics.